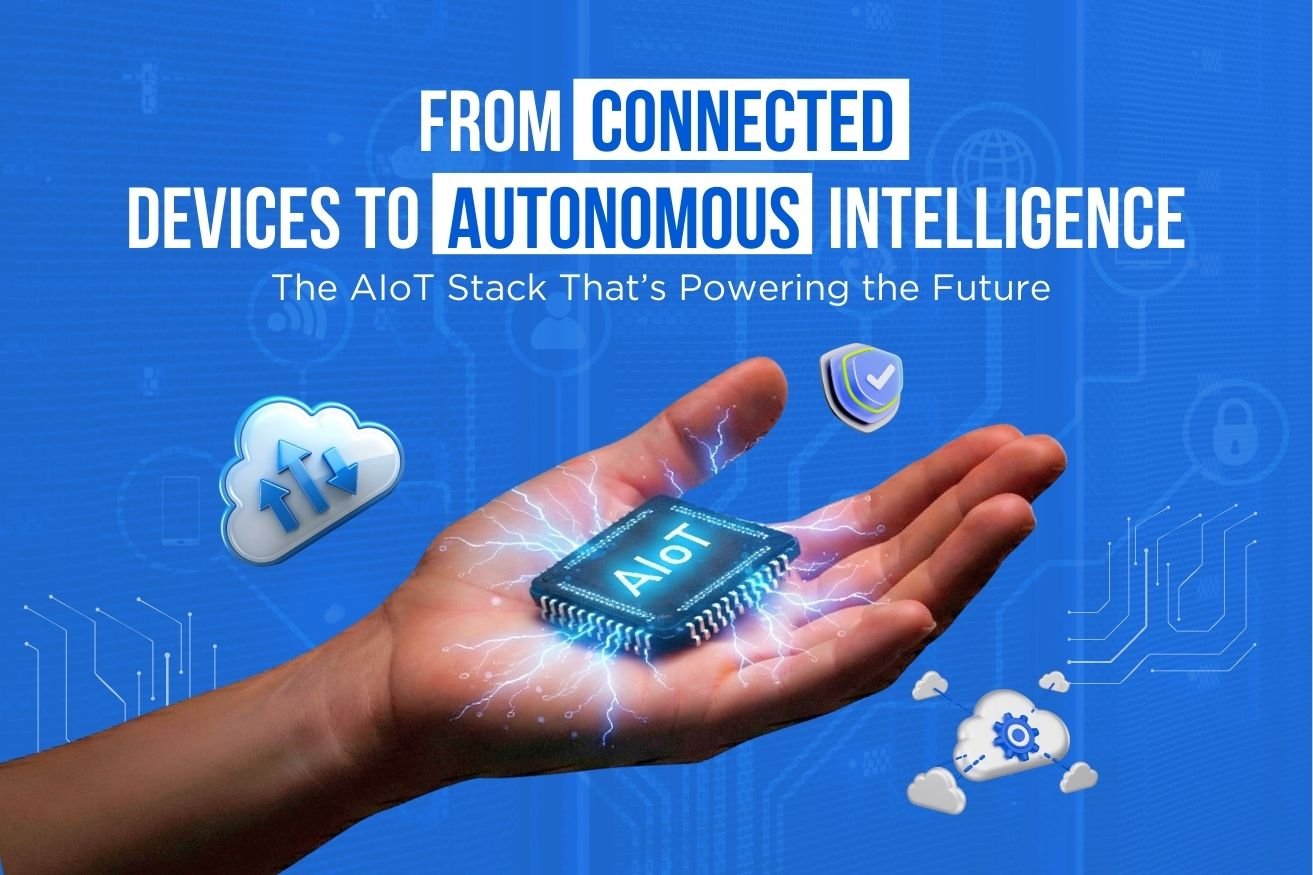

In today’s hyper-connected world, businesses are shifting from basic IoT systems to AI-powered IoT (AIoT) architectures that deliver real-time intelligence, automation, and predictive decision-making. The quality of this intelligence depends entirely on the quality of the data pipeline.

This guide breaks down the 15-step AIoT data pipeline, showing exactly how raw sensor readings evolve into smart, autonomous actions.

Why the AIoT Pipeline Matters

The journey from raw signals to real-time automation requires multiple layers: sensing, filtering, routing, analyzing, modeling, securing, and optimizing. A mature AIoT architecture ensures:

- Faster response times

- Accurate predictions

- Lower bandwidth & cloud cost

- Higher reliability

- Secure data handling

- Automation that works every time

1. Data Capture: Sensing the Environment

Sensors collect temperature, motion, humidity, sound, vibration, energy usage, and machine status. These raw readings form the foundation of all intelligent decisions.

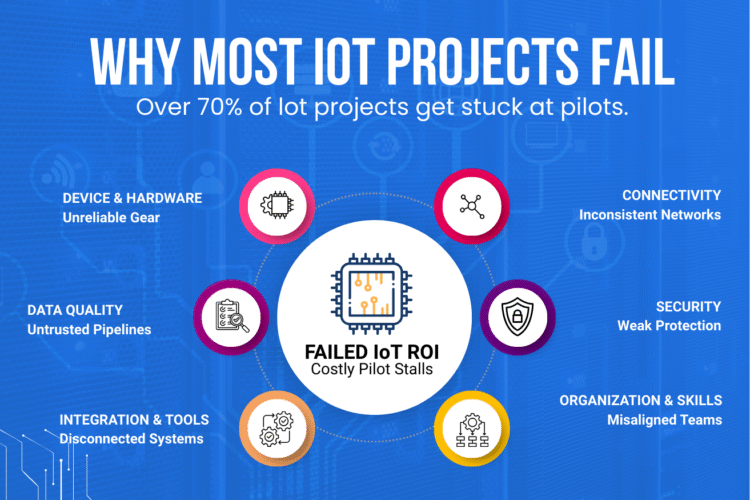

2. Device Connectivity: Getting Data to the Network

IoT devices connect via Wi-Fi, BLE, LoRaWAN, NB-IoT, LTE-M, 4G/5G, Ethernet, CAN, or Modbus. Strong connectivity ensures low latency and secure transmission.

3. Edge Filtering: Reducing Noise and Bandwidth

Devices filter redundant readings, noise, and invalid spikes to reduce bandwidth, battery usage, and cloud costs.

4. Data Aggregation: Structuring the Streams

Aggregation organizes multiple sensor streams into structured, usable datasets.

5. Gateway Management: Secure Routing

Gateways handle authentication, protocol translation, buffering, routing, and connectivity fallback.

6. Stream Processing: Real-Time Insights

MQTT, Kafka, AWS IoT Core, and Azure IoT Hub enable real-time anomaly detection, alerts, visualizations, and automations.

7. Cloud Storage: Building the Data Foundation

Clean and structured data is stored in data lakes, time-series databases, and SQL/NoSQL systems for long-term analysis and AI development.

8. Data Transformation: Preparing for AI

Data is normalized, enriched, cleaned, and converted into usable machine learning features.

9. Visualization Layer: Real-Time Dashboards

Dashboards reveal insights such as machine performance, asset health, environmental patterns, and user behavior.

10. Security & Compliance

Includes encryption, authentication, access control, device identity, compliance (GDPR/HIPAA), and secure OTA updates.

11. Predictive Modeling

Machine learning forecasts failures, energy usage, anomalies, and operational risks — making systems proactive.

12. Edge AI Execution

Lightweight ML models run on microcontrollers and gateways for instant, offline-capable intelligence.

13. Automated Workflows

Systems trigger actions like alerts, actuator movement, environmental control, and energy optimization in real time.

14. Self-Healing Systems

AIoT systems auto-recover by restarting devices, re-routing traffic, adjusting parameters, and self-calibrating sensors.

15. Continuous Optimization

Feedback loops continuously improve AI models, system performance, calibration, and decision accuracy.

Conclusion: Future-Ready AIoT Systems

Whether you’re building a smart factory, smart home device, or industrial automation system, following this 15-step pipeline ensures your product is scalable, secure, intelligent, and future-proof.