The IoT in Manufacturing Industry

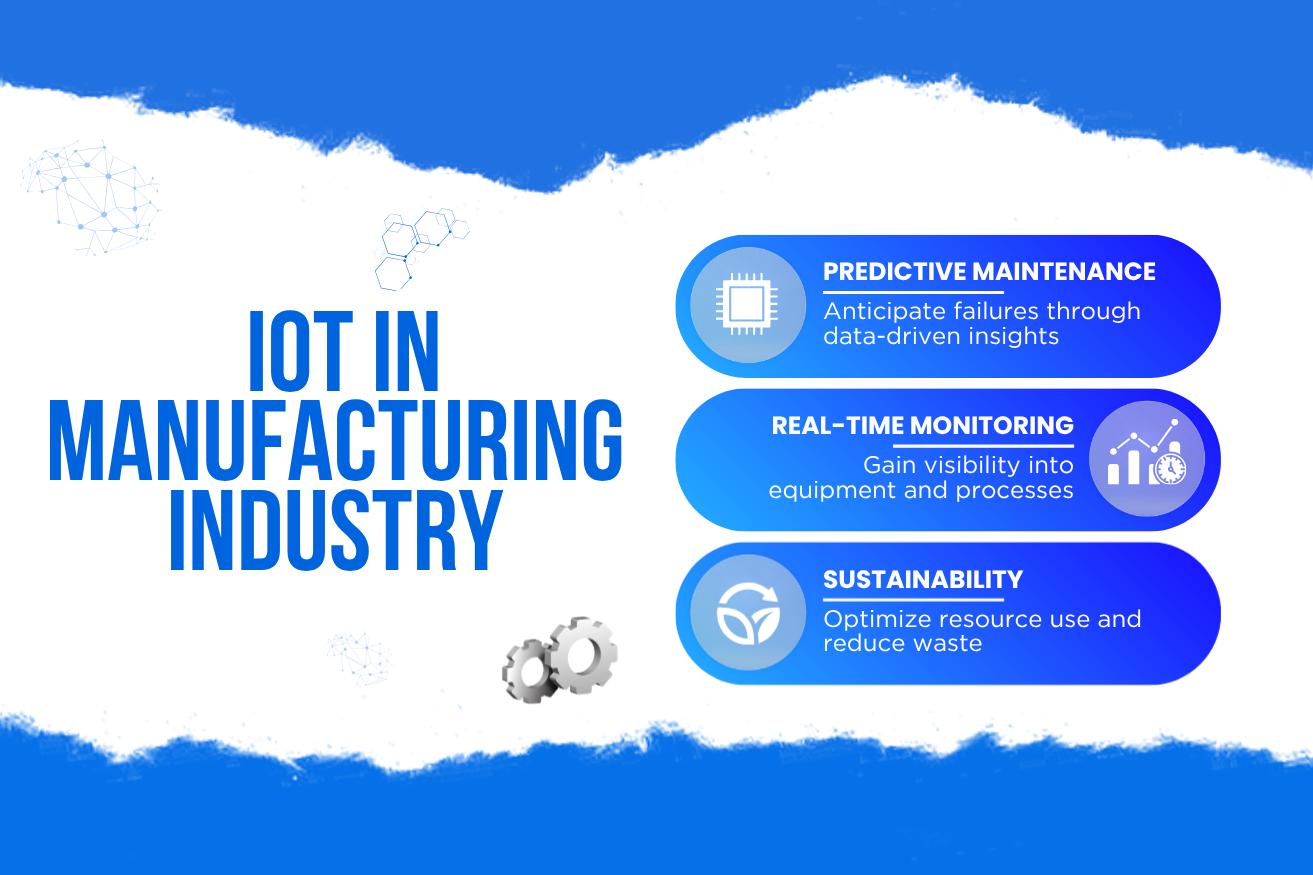

The IoT in manufacturing industry is redefining how factories operate. From intelligent machines to predictive maintenance, IoT is helping manufacturers optimize performance, cut costs, and make data-driven decisions. In today’s fast-evolving industrial landscape, IoT for manufacturing is not just a competitive advantage — it’s becoming a necessity.

Understanding IoT in the Manufacturing Industry

The Internet of Things (IoT) refers to a network of connected devices that communicate, collect, and exchange data. In the manufacturing industry, IoT connects machines, sensors, and software systems into a single digital ecosystem.

This integration allows factory operators to monitor performance in real time, predict equipment failures before they happen, and automate repetitive tasks — making production smarter and more efficient.

Unlike traditional automation, IoT industrial solutions extend connectivity beyond factory walls, integrating supply chains, logistics, and even customer data into one streamlined workflow.

Key Applications of IoT in Manufacturing

IoT applications span across multiple layers of the industrial value chain. Here are the most impactful use cases driving the IoT industry growth:

- Predictive Maintenance: Connected sensors monitor equipment health, vibration, temperature, and energy consumption. Using analytics and machine learning, industrial IoT manufacturing platforms can predict when a machine will fail — reducing downtime and maintenance costs.

- Real-Time Production Monitoring: IoT devices provide instant visibility into production lines, enabling operators to track throughput, performance, and bottlenecks. This IoT for manufacturing capability leads to faster decisions and optimized operations.

- Asset Tracking and Inventory Management: Smart tags, RFID sensors, and IoT tracking systems ensure materials, components, and finished goods are always visible throughout the supply chain. This prevents losses and improves logistics efficiency.

- Quality Control and Process Automation: IoT-enabled cameras and sensors detect defects in real time, allowing automated adjustments. In industrial IoT manufacturing, this leads to higher product quality and less waste.

- Energy Optimization: IoT platforms analyze power usage patterns to identify inefficiencies and reduce energy consumption — a crucial factor for sustainable, cost-effective operations.

Benefits of IoT in the Manufacturing Industry

Adopting IoT solutions delivers significant benefits to manufacturers across all scales:

- Operational Efficiency: Automated monitoring and real-time analytics reduce manual interventions and errors.

- Predictive Insights: Early detection of issues prevents costly breakdowns.

- Improved Supply Chain Visibility: End-to-end asset tracking strengthens control and transparency.

- Reduced Energy Costs: Smarter energy management improves sustainability.

- Scalability: Cloud-based IoT systems allow seamless scaling of connected devices across plants.

These advantages explain why the IoT industry growth has accelerated in recent years — with more manufacturers transitioning toward connected, data-driven models.

Challenges and Considerations

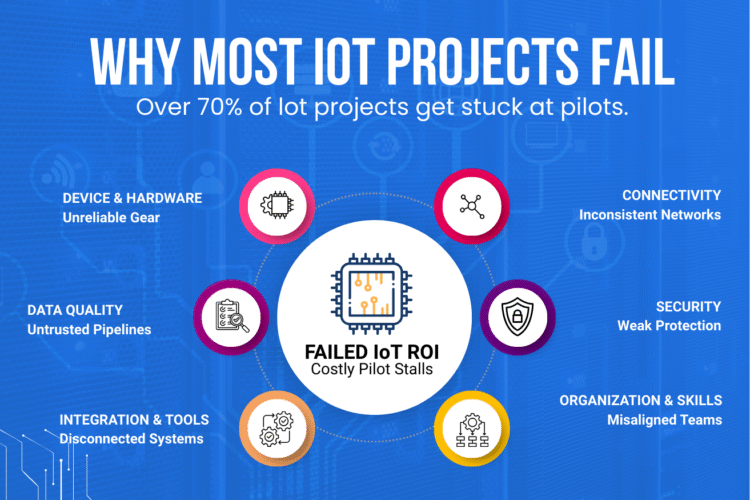

While the benefits are clear, implementing IoT in manufacturing isn’t without challenges:

- Cybersecurity Risks: Increased connectivity means greater exposure to attacks.

- Integration Complexity: Connecting legacy systems with new IoT platforms requires careful planning.

- Data Overload: Managing and analyzing vast amounts of data can be overwhelming without proper architecture.

- Initial Costs: Sensor deployment and network infrastructure can be expensive upfront, though long-term ROI is substantial.

Future Outlook of Industrial IoT Manufacturing

The future of IoT in the manufacturing industry lies in the convergence of AI, 5G, and edge computing.

With faster communication, smarter analytics, and decentralized processing, factories will evolve into fully autonomous, adaptive systems capable of self-optimization.

Global forecasts indicate that the industrial IoT manufacturing market will continue to grow rapidly, driving digital transformation and sustainability across every industrial sector.

Why Choose MetaDesk Global for IoT Manufacturing Solutions

At MetaDesk Global, we specialize in end-to-end IoT product development — from firmware and PCB design to cloud connectivity and predictive analytics.

Our engineering expertise enables manufacturers to:

- Deploy connected devices that collect actionable data.

- Build secure and scalable IoT architectures.

- Integrate edge intelligence and AI-driven automation.

We help turn data into value, transforming traditional manufacturing into smart manufacturing.

Conclusion

The IoT in manufacturing industry is not just about connecting machines — it’s about creating intelligent ecosystems that think, adapt, and evolve.

By adopting IoT for manufacturing, businesses can unlock higher efficiency, safety, and innovation.

At MetaDesk Global, we’re driving the IoT industry growth by designing industrial solutions that make every operation smarter, faster, and more sustainable.