The wearable technology industry has exploded in recent years, transforming from simple fitness trackers into sophisticated medical devices, industrial safety gear, and smart consumer products. According to market research, the global wearable market is projected to surpass $150 billion by 2030, driven by innovations in healthcare monitoring, IoT connectivity, and AI integration.

Wearables have moved far beyond counting steps. Today, they are being designed to:

- Monitor vital health signals such as heart rate, oxygen saturation (SpO₂), and ECG

- Improve workplace safety through fall detection and fatigue monitoring

- Enhance sports performance with biomechanical tracking

- Provide hands-free interaction in AR/VR environments

- Deliver personalized wellness insights with the help of cloud-based analytics

But developing a wearable device that is accurate, reliable, and manufacturable requires a multi-disciplinary engineering effort.

What Makes Wearable Development Challenging?

Unlike traditional electronics, wearables are:

- User-facing and body-worn → comfort, ergonomics, and aesthetics matter as much as performance.

- Battery-powered → devices must run for days or weeks on a single charge, requiring low-power design and efficient firmware.

- Always connected → BLE, Wi-Fi, and even cellular modules are integrated for real-time communication.

- Data-sensitive → health and personal data requires end-to-end encryption, secure boot, and OTA updates.

- Mass produced → enclosures must be optimized for injection molding and other scalable manufacturing methods.

This complexity means wearable development isn’t the job of a single engineer. It requires hardware engineers, firmware experts, PCB designers, mobile app developers, and mechanical enclosure specialists working in harmony.

The MetaDesk Global Approach

At MetaDesk Global, we deliver end-to-end wearable development by combining:

- Hardware & PCB design for miniaturization and low power

- Firmware development with RTOS and BLE stacks

- Mobile app integration for monitoring, insights, and OTA updates

- Mechanical enclosure design for comfort and manufacturability

This team-based model reduces delays, avoids miscommunication, and accelerates the journey from idea to production.

Case Study: Our Anti-Snoring Wearable

One of our in-house projects is a wearable anti-snoring device designed to improve sleep quality.

Stage 1: Idea & Research

The concept was straightforward — detect snoring and intervene gently without waking the user. We researched acoustic patterns, haptic feedback methods, and ergonomic requirements for overnight use.

Stage 2: Proof of Concept (PoC)

We built a quick-turn prototype with:

- A microphone to detect snoring

- A vibration motor to nudge the wearer

- A basic PCB with BLE

- A test mobile app for simple pairing and monitoring

This validated the core idea.

Stage 3: Minimum Viable Product (MVP)

From PoC, we engineered an MVP:

- Microphone + vibration motor for accurate detection and safe feedback

- Custom PCB for compactness and energy efficiency

- BLE firmware + mobile app for real-time monitoring, vibration control, and sleep data visualization

- OTA update capability through the mobile app for continuous improvements

- Skin-safe enclosure, ergonomically designed for overnight comfort and made injection-molding-ready for small-batch production

Why Mobile Apps Are Critical in Wearables

The mobile app acts as the bridge between user and device, turning hardware into a complete product ecosystem. For our anti-snoring wearable, the app:

- Guides setup and BLE pairing

- Tracks nightly sleep patterns

- Lets users adjust vibration thresholds

- Provides long-term insights and analytics

- Handles OTA firmware updates seamlessly

Without the app, the device would remain a “gadget.” With it, it becomes a health solution.

The Future of Wearables

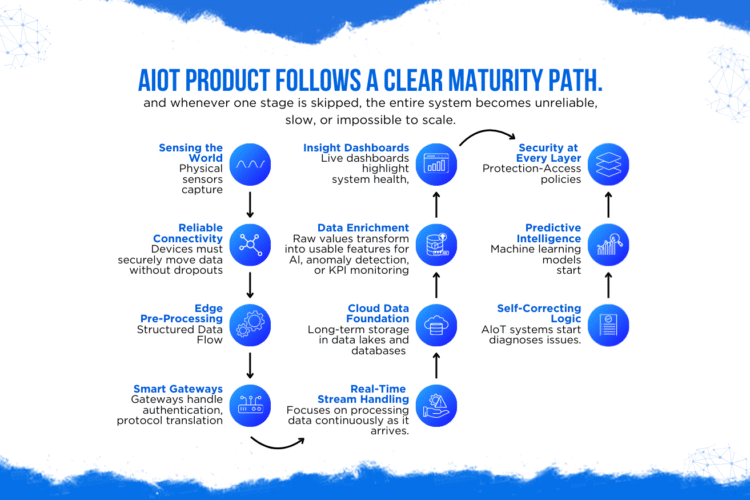

Wearables will continue to evolve into medical-grade devices, industrial safety tools, and lifestyle companions. Trends like AI-powered anomaly detection, flexible electronics, and cloud-connected health dashboards will shape the next generation of devices.

At MetaDesk Global, we’re already working on integrating these technologies into real-world products, helping startups and enterprises move from concept → prototype → MVP → production.

Conclusion

Wearables are more than just gadgets — they’re becoming essential tools in healthcare, fitness, and industry. But creating a wearable that is accurate, reliable, and manufacturable requires collaboration across disciplines.

Our journey with the anti-snoring device demonstrates how an idea can become a production-ready MVP when hardware, firmware, mobile apps, and enclosure design come together.

💡 Have a wearable product idea? At MetaDesk Global, we can help you turn it into reality.