Why IoT Devices Fail in the Real World

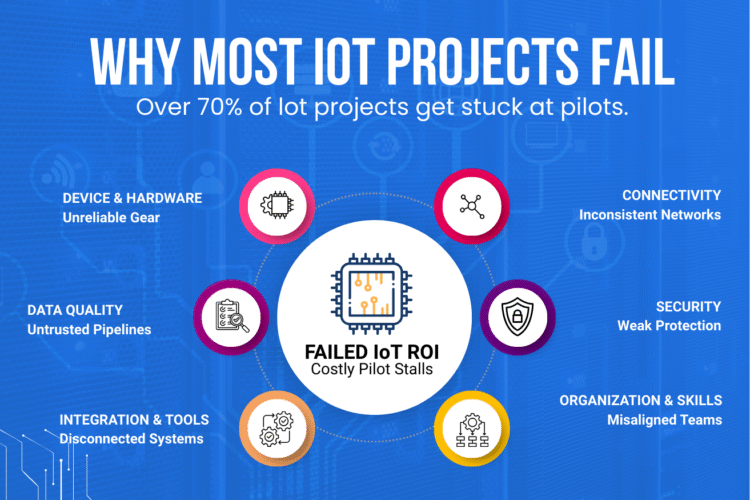

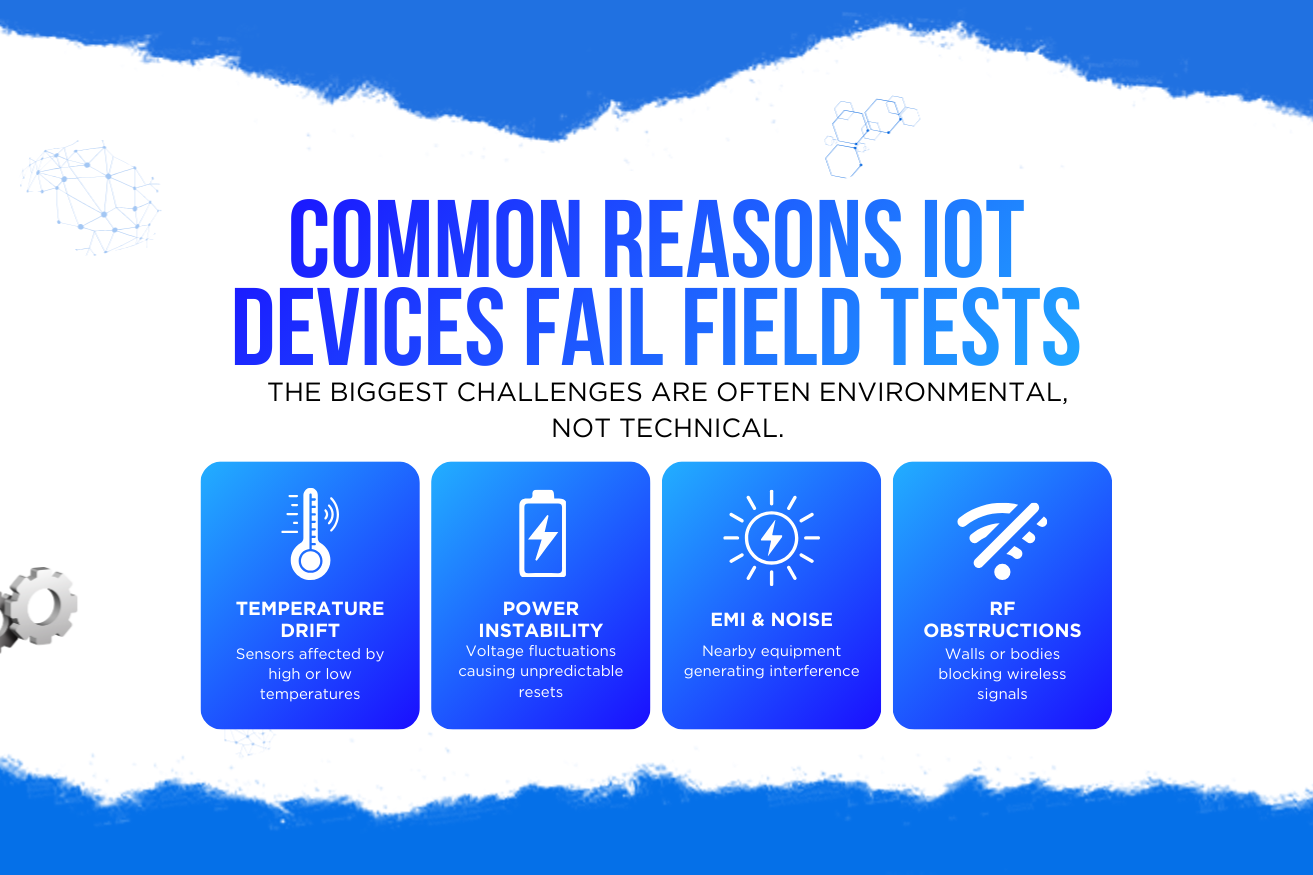

In the world of connected products, teams often assume the hardest part of IoT development is writing flawless firmware, selecting the right microcontroller, or designing a stable PCB. But when real-world deployment begins, a different story emerges: most IoT devices fail in field tests due to environmental factors—not software defects.

Understanding these hidden pitfalls is crucial for building IoT products that are reliable, scalable, and ready for real-world use.

The Real Reason IoT Devices Fail: Environmental Conditions, Not Code

Laboratory testing gives a false sense of security. Controlled temperatures, clean power, and zero interference create an ideal environment—one that does not exist outside your office. Once IoT devices hit industrial plants, farms, construction sites, or customer homes, they face harsh variables that can quickly expose weaknesses.

1. Temperature Drift — The Silent Sensor Killer

Why Temperature Impacts IoT Performance

- Heat beyond 45°C

- Cold below 10°C

- Rapid temperature swings

- Solar radiation effects

Even high-quality sensors can behave unpredictably outside standard test conditions. Sensors begin to drift, calibration breaks, and data accuracy plummets.

How to Prevent It

- Choose sensors with real-world field data, not just datasheet promises

- Test devices across full operating temperature ranges

- Implement calibration correction algorithms

2. Power Noise and Voltage Instability

The Problem

Power fluctuations are one of the top causes of random resets and device instability. Even a small spike on a 3.3V line can corrupt memory, reset the microcontroller, and create unpredictable behavior. Most of these issues remain undetected during desktop testing because USB-powered testing masks real power conditions.

The Solution

- Add proper capacitors, LC filters, and transient suppression

- Test with real batteries, solar chargers, and noisy power supplies

- Validate ripple and load variations

3. EMI & Interference from Surrounding Equipment

Why EMI is a Major IoT Threat

In industrial settings, devices share space with motors, relays, welding units, power converters, and high-current equipment. These create electromagnetic fields that can disturb sensor readings, damage communication lines, and cause spurious resets. Your code may be perfect—but hardware around you may not be.

Mitigation Techniques

- Add shielding to sensitive circuits

- Use twisted-pair cabling

- Increase spacing from EMI-heavy equipment

- Add ferrite beads and EMI filters

4. Real-World RF Issues: Poor Wi-Fi, LoRa, and BLE Coverage

What Happens in the Field

- Concrete and metal walls weaken Wi-Fi

- Human bodies absorb BLE signals

- Trees and buildings affect LoRa line-of-sight

- Multipath reflections distort RSSI values

Theoretical range does not equal real range.

How to Improve RF Reliability

- Conduct on-site RF surveys

- Optimize antenna placement and orientation

- Add fallback communication (BLE + Wi-Fi, LoRa + Cellular)

- Tune transmit power dynamically

Why Real-World Testing Matters More Than Lab Testing

IoT engineering is not just about algorithms or PCB design. It’s about understanding the physics of the real world. That’s why devices that work flawlessly on your desk often fail outdoors. The best IoT companies build reliability by testing outdoors and in extreme conditions, simulating power loss, EMI, and RF interference, and stress-testing sensors in actual deployment environments.

Field testing isn’t optional—it’s essential.

The MetaDesk Engineering Philosophy: Test in the Wild, Not Just the Lab

At MetaDesk Global, we design IoT and embedded systems that thrive in real-world conditions. Our engineering teams follow a field-first approach that includes:

- Multi-environment validation

- EMI and RF robustness testing

- Power stability analysis

- Sensor drift verification

- Hardware-in-loop test automation

Because real IoT reliability begins where the laboratory ends.

Final Thoughts — Reliability Is Earned, Not Assumed

Most IoT failures come from ignoring environmental factors early in the design lifecycle. By embracing real-world testing and engineering for harsh environments, companies can reduce risk, cut redesign costs, and ship devices that customers trust.

IoT engineering is 50% design, 50% understanding the environment—and success belongs to teams that master both.